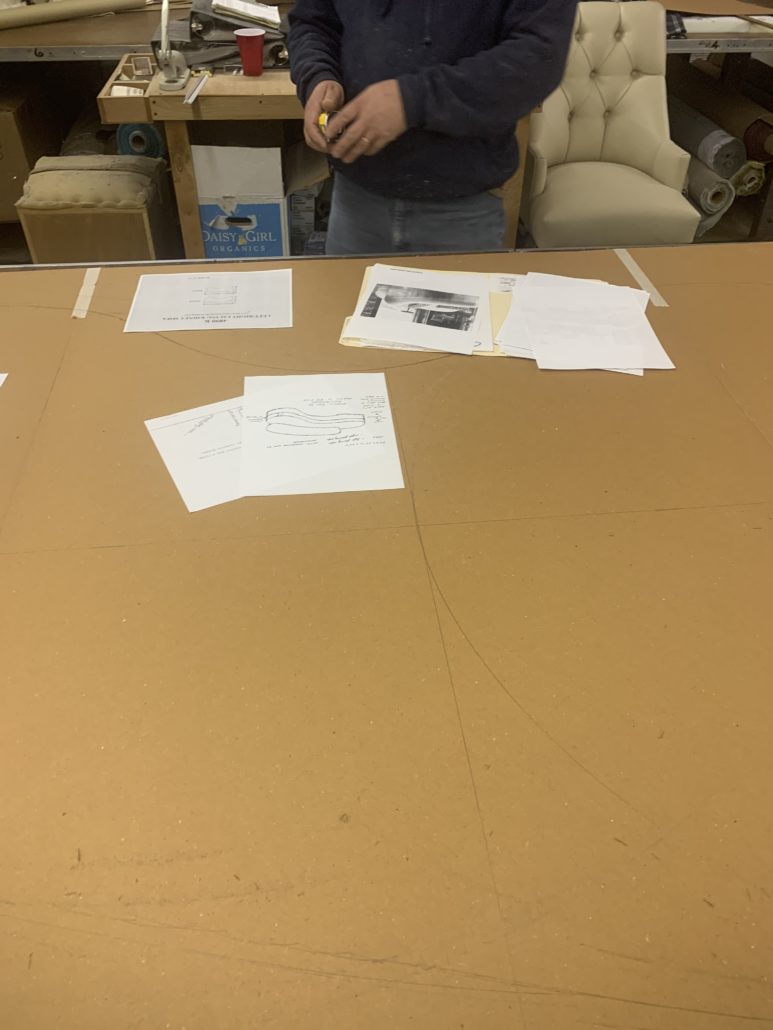

“Every artist was first an amateur”- Ralph Waldo Emerson. I started working for my families business at the age of 12. Every summer until I was 18 I would work the an early morning shift. I have tried to learn as much as possible in my 20 years of working here but I still learn things on a weekly basis. When it comes to custom furniture, some of the pieces we have never done before. We have an general idea of what a custom piece of furniture entails but we often learn a lot through the process. That process begins 90% of the time with a scaled drawing. For this particular custom sofa we are talking about to today, that was indeed the case. We were working off a picture from an older magazine. We had the overall size of the custom sofa to go by but no other dimensions. I have seen thousands of pieces of furniture in my life, some custom, some standard, which has given me a certain ability proportionate the furniture. I use this to determine the dimensions for the piece based on the picture provided. For this custom sofa the tricky part was getting the shape of the curve proportionate and functional at the same time.  After the scaled drawing is approved the next step for the custom sofa was a actual size template of the curve to use for cutting the wood. I draw this up myself and then consult my frame shop. I make sure my shape isn’t going to present and problems for them in the manufacturing process. I also get there opinion on the overall shape or style. They have been making custom frames for 30 years and I value there opinion. Once everything is gone over with the shape, the details for the custom sofa frame are discussed. Those things are, how high do we make the front rail to achieve the desired seat height? How much to we take off on the back frame height for the padding being added? Where do we need pulls? and etc. After this is all determined the custom sofa’s frame is made.

After the scaled drawing is approved the next step for the custom sofa was a actual size template of the curve to use for cutting the wood. I draw this up myself and then consult my frame shop. I make sure my shape isn’t going to present and problems for them in the manufacturing process. I also get there opinion on the overall shape or style. They have been making custom frames for 30 years and I value there opinion. Once everything is gone over with the shape, the details for the custom sofa frame are discussed. Those things are, how high do we make the front rail to achieve the desired seat height? How much to we take off on the back frame height for the padding being added? Where do we need pulls? and etc. After this is all determined the custom sofa’s frame is made.  After the frame is made, pictures are sent to the client to ensure they like the shape of the custom sofa now that it is in its full size. Once approved the next step is to inspect the fabric. We inspect the fabric for (3) reasons, 1) To see if there is a particular direction the fabric must run if not noted on the purchase order, 2) To make sure there are no defects with the fabric, and 3) To see how much give or stretch there is with the fabric. All of this helps us determine our upholstery details. I write up the cutting order personally and then review it with the cutters. We pad everything up and make our cuts. Then its all left up to the upholsters. For this particular custom sofa, the deck was the hardest part of the cutting and upholstery process. We hade to make pleat cuts in the fabric for it to curve around the deck in one piece.

After the frame is made, pictures are sent to the client to ensure they like the shape of the custom sofa now that it is in its full size. Once approved the next step is to inspect the fabric. We inspect the fabric for (3) reasons, 1) To see if there is a particular direction the fabric must run if not noted on the purchase order, 2) To make sure there are no defects with the fabric, and 3) To see how much give or stretch there is with the fabric. All of this helps us determine our upholstery details. I write up the cutting order personally and then review it with the cutters. We pad everything up and make our cuts. Then its all left up to the upholsters. For this particular custom sofa, the deck was the hardest part of the cutting and upholstery process. We hade to make pleat cuts in the fabric for it to curve around the deck in one piece.  Once this was figured out, which took a few tries, another picture of the custom sofa was sent for approval. Once approved the cushion patterns are made. The cushion fill is determined and the piece is completed. It takes us around 3-4 weeks from frame made to completion.

Once this was figured out, which took a few tries, another picture of the custom sofa was sent for approval. Once approved the cushion patterns are made. The cushion fill is determined and the piece is completed. It takes us around 3-4 weeks from frame made to completion.